Quality

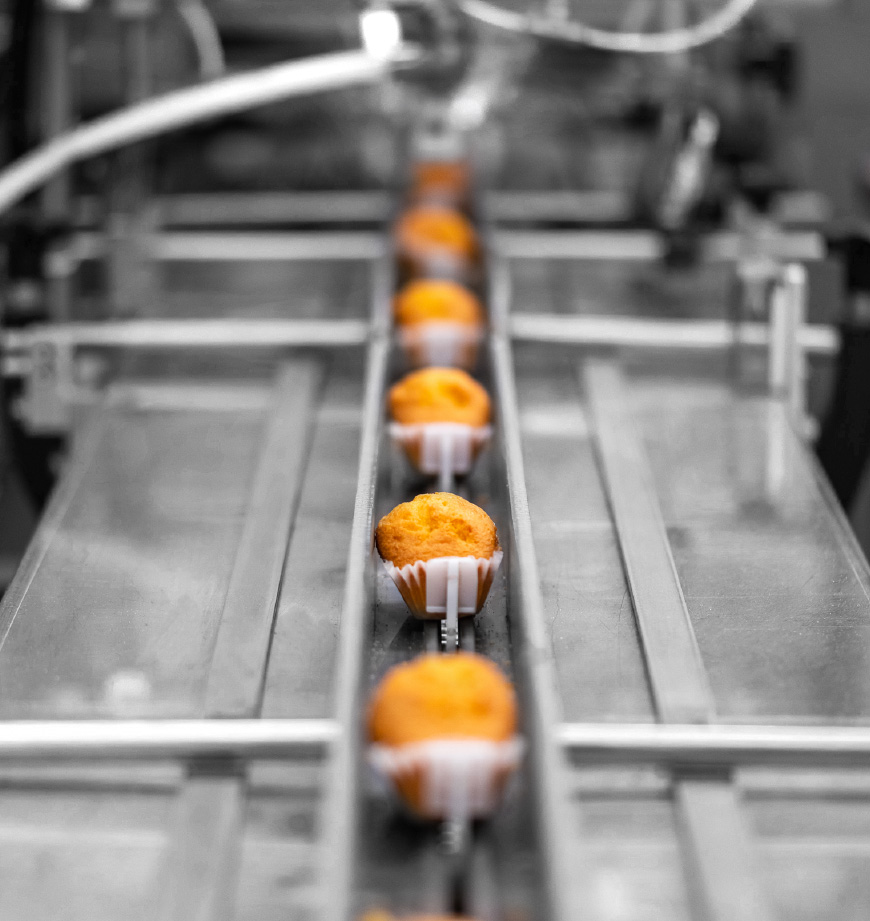

Alpipan’s entire production cycle undergoes a rigorous and comprehensive series of quality controls to ensure the food safety of the products placed on the market and to comply with strict production standards. Thanks to packaging in a protective atmosphere and the use of a sourdough starter, our breads have a shelf life of 6 months, which means they can also be exported overseas. Cutting-edge diagnostic tools enable line checks to be carried out on 100% of the packages to ensure that they are airtight. Alpipan’s total quality approach has distinguished it for over sixteen years, making it one of the leading manufacturers of gluten-free bakery products for private labels in both Europe and America.